- Udyog Vihar, Gurugram, Haryana

- GST NO. : 06ADMPF3512D1Z3

- +91-9213687143, +91-9910770321

50 Piece (MOQ)

| Business Type | Manufacturer, Supplier |

| Material | Copper |

| Surface Finishing | Polished |

| Color | Brown |

| Click to view more | |

Preferred Buyer From

| Location | Anywhere in India |

Product Details

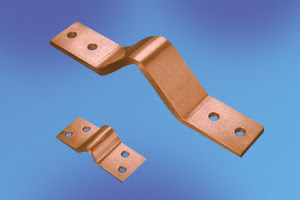

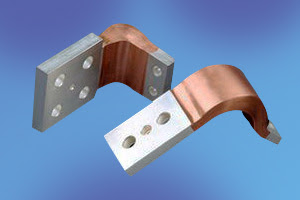

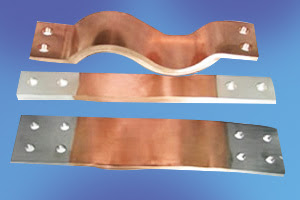

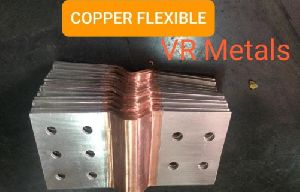

We are introducing ourselves as VR METALS AND ENGINEERS ISO 9001:2015 CERTIFIED COMPANY the leading manufacturers of Flexible Connectors made by adopting a special technique of Hot Pressed Electro Fusion Welding Process for carrying high current, to minimize mill volt drop, to avoid temperature rising, to reduce power losses & to save energy consumption. We are using electrolytic Grade & High Conductivity Copper Foils and wire to produce the best result. Copper components are the most important part in the transmission system. They take care of the thermal & dynamic stresses to avoid breakage of insulators due to inherent vibrations of the equipment under operation. The technique acquired by us gives the friction free flow of current to provide better life to the flexible.

PRODUCT RANGE

Copper Strip Flexible,Aluminum Strip Flexible,Copper Braided Flexible,Copper Braided Links in round & Flat,Stranded Wire Rope bare, silver & tinned finish,Copper Rods,Special Copper components for any configuration

VR METALS AND ENGINEERS ISO 9001:2015 CERTIFIED COMPANY is catering to the need of various industries such as: Electrical Control Panel Industries,Power Distribution Industries,Switchgear Industries,Railway & State Electricity Boards,Atomic Power Plants,Heavy Chemical Industries,Carbon Brush Industries,Thermal Power Projects,Hydro Power Projects

Besides the above many more industries are using flexible connectors for resistance welding machines, circuit breakers and galvano engineering etc.

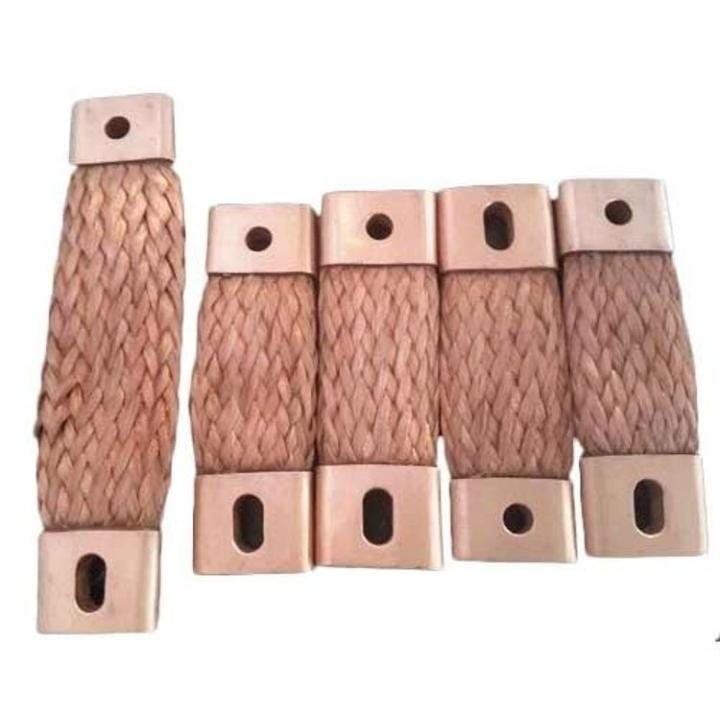

BRAIDED FLEXIBLE : Braided copper connectors solve high-voltage connectivity problems created by vibration from generators and transformers. When used as the initial connector from vibration-producing equipment to a power distribution network, flexible connectors isolate the main electrical grounding busbar work from the menace of vibration. And while flexible braided connectors are more expensive than using copper bus bar, copper braided flexible returns the investment by cutting the potential cost of down time, maintenance and energy loss created by loose electrical connections. SPECIFICATIONS :Wire Condition: Bare, Tinned (Hot Dip),Material: ETP Grade Cu wire(Annealed),Wire Diameter: 0.10mm – 1.10mm,Range: 1 sq.mm – 4000 sq.mm,Plating on solid contact area: Bare, Tinned & Silver coating finish.

COPPER STRANDED WIRE ROPE FLEXIBLE A stranded copper wire refers to a group of copper wires that are braided or twisted together. A stranded copper wire is more flexible and easier to install than a single strand copper wire of the same cross section. It also improves wire longevity for applications with moderate to high vibration.A particular cross-section of a stranded conductor essentially gives better resistance characteristics & flexibility.

SPECIFICATIONS:-Wire Condition: Bare & Tinned (Hot Dip),Material: ETP Grade CU wire (Annealed)Wire Diameter: 0.10mm – 1.10mm,Range: 10 sq. mm to 500 sq.mmPlating on contact area: Bare, Tinned & Silver coating finish.

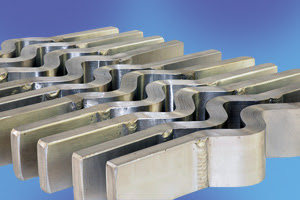

For a long time the concept of copper flexible was just stacking together bunches of foils and connecting the same. Further, riveting at the ends was started and was further improved by soldering/brazing/welding. But the loss of energy was never considered/assessed. Later on, as the cost of energy increased tremendously, the technique of hot pressed electro fusion process for Copper Flexible & tig welding process for aluminum flexible was put in use which is the latest trend and resulting into substantial savings in energy cost. SRG is using the same technique.

SPECIFICATIONS

- Foil Condition: Bare

- Material: ETP grade

- Foil Thickness: 0.05mm – 1.00mm

- Width Range: 10mm – 300 mm

- Plating on fusion area: Bare, Tinned & Silver coating finish.